3D printing in and of itself is a revolutionary manufacturing process that’s taking the world by storm. In recent times we’ve seen a host of innovations in both the capabilities and applications of this new technology. However in the last few weeks we’ve seen possibly the greatest innovation yet: a revolutionary new 3D printing process that promises to increase throughput as well as opening up the possibility to easily print objects with geometries that prove challenging to conventional 3D printers. The team at Carbon3D developed this innovative new process, completely rethinking the way 3D printing is done.

Conventional 3D printers build and object layer by layer, strand by strand, to achieve quite pleasing results. However this process can take hours to produce the final printed object, and one of the motivating factors behind the development of this new process was to reduce this printing time from hours to minutes. This new process is referred to as CLIP (Continuous Liquid Interface Production) and is a remarkable new way of looking at printing continuous solid objects from a liquid medium. The printed object appears to continuously rise quite rapidly out of a bath of liquid media in a matter of minutes. CLIP not only increases throughput but, thanks to the continuous nature of the production process, creates stronger printed objects by reducing microscopic imperfections.

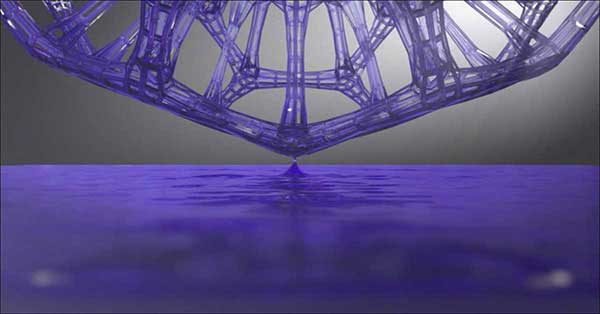

The CLIP process itself represents a breakthrough in chemical engineering and materials science, but unfortunately is a little complex to be treated briefly. This animation shows how the CLIP process works and compares it to conventional 3D printing methods. Moreover Joseph DeSimone, the CEO of Carbon3D, gave an inspiring TED talk about CLIP technology and its implications for the future of 3D printing. Anyone fascinated by 3D printing technologies will find his TED talk to be of great interest.